Water Pump Pulleys: Function, Types, Materials & Replacement Guide

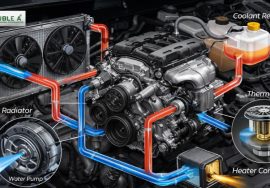

Of the intricate ecosystem that is an engine cooling system, all parts should operate in perfect harmony in order to avoid thermal damage. Although the water pump is the heart of the system, the water pump pulleys are where the key to the operation is to offer the pulse. The absence of a high-precision pulley will result in the inability to circulate a coolant, which poses an immediate risk to the engine.

In this guide, we disassemble the mechanics, materials, and maintenance of the water pump pulley used in automotive and industrial purposes.

Introduction to Water Pump Pulleys

Water pump pulleys are circular mechanical machineries on the water pump shaft. Their main role is to take rotational energy, which is on the crankshaft of the engine, and transfer it to the pump’s internal impeller. They serve as the connection point to the engine cooling system parts, provide the mechanism of coolant flow that ensures that your engine does not exceed the safe operating range of temperatures.

A radiator and water pump pulley system in a small car or a heavy-duty industrial machine, the design of the pulley is used to dictate the flow rate of the coolant, depending on the pulley ratio and the speed of the water pump.

How Water Pump Pulleys Work

Belt-Driven Mechanism

The majority of modern engines have a belt-driven water pump pulleys. Two types of belts are used in turning the pulley:

- Serpentine Belt Pulley: It is a single belt, long and ribbed, used to power various peripherals such as the alternator, AC compressor, water pump, etc.

- V-Belt Water Pump Pulley: This type of pulley is a typical wedge-shaped design belt that is common in older models or in certain niche diesel engine pump pulleyies.

Connection between the Crankshaft and the Pulley

The crankshaft of the engine has a drive pulley. The movement of the crankshaft is then transferred to the water pump pulley by the belt. This continuous rotation drives the coolant circulation pulley, which keeps the engine block at a stage where the causes of overheating engines are critical.

Types of Water Pump Pulleys

Based on Vehicle Type

- Car Water Pump Pulley: This is optimized with high-RPM passenger cars, with special consideration given to the lightweight and minimum noise.

- Truck Water Pump Pulley: It is designed to meet the high-torque commercial engine, which is subjected to long-haul stress.

- Tractor Water Pump Pulleys: These are rugged in nature to operate in farm settings where dust and vibration are an order of the day.

- Earthmover Engine Pulleys: This is an oversized heavy-duty mining and construction machinery pulley.

Based on Usage

- OEM Water Pumps Pulley: This type is made to the same exact specifications as the original engine manufacturer (e.g., the standards that Makhija International uses towards their 12+ OEM customers).

- Aftermarket Water Pump Pulleys: Replacement parts are of high quality, and they are created to perform at least as well as original parts.

- Heavy Duty Water Pump Pulleys: Heavy-duty models that are reinforced for use in special-purpose industrial or racing applications.

Materials Used in Water Pump Pulleys

It is an inhumane environment inside the hood that demands materials that can stand the heat, friction, and chemical exposures.

- Aluminum Water Pump Pulleys: Are lightweight and good at minimizing parasitic drag; they are commonly made with billet aluminum pulleys to use in high performance applications.

- Steel Water Pump Pulleys: Steel is the standard in the industry in terms of durability and high tension.

- Cast Iron Pump Pulley: A more favorable choice in industrial engines of heavy-duty because it has better vibration-damping characteristics and can withstand high heat.

The Manufacturing Advantage: Best manufacturers are CNC machining their water pump pulleys to make concentricity perfect. This stops the wobbles from increasing the life of the belt and the pump itself. Also, powder-coated pulleys are used or plated finishes to make sure that they are corrosion-resistant pulleys even when in a humid or salty environment.

Signs of a Faulty Water Pump Pulley

Failure to maintain a bad water pump pulley may result in a broken belt or the engine being seized. Watch for these symptoms:

- Engine Overheating: In case the pulley does not rotate or becomes stuck, the flow of coolant is discontinued.

- Belt squealing Noise: When you hear a squeal of high pitch that is a good sign that you have a glazed belt or a misaligned pulley.

- Pulley Wobbling: When stationary can be seen to vibrate; this is an indication of a bent shaft or damaged engine pulley alignment.

- Coolant Leakage: In some cases, a malfunctioning pulley bearing may tear the seal on the pump, resulting in visible leaks.

- Misaligned Serpentine Belt Pulley: When the belt is walking off the side of the pulley, be it due to a worn pulley or not, stop and have it looked into.

Water Pump Pulley Replacement Guide

When to Replace

It is advisable that the pulley be inspected whenever replacing the water pump or when you observe the symptoms of a faulty water pump pulley. The cost of the replacement of the pulley and the belt is cheaper, as labor to access the pump is usually high.

Installation Essentials

- Proper Tools: An iron rod with a hook is used to extract the pulley so that no harm is caused to the shaft of the pump.

- Torque Specs: It is always essential to follow the torque specs of water pump pulley bolts of a particular water pump to ensure that they do not shear or back out.

- Engine Pulley Alignment: This is to check that the belt is in the grooves. A 1mm misalignment will decrease the lifespan of a belt by half.

Choosing the Right Water Pump Pulley Manufacturer

In cases where you require you to shop online to purchase water pump pulleys as well as source out a fleet, seek out a partner who has established infrastructure. Makhija International Private Limited is unique in that it provides:

- OEM Manufacturing Capability: Years of experience in providing key automotive brands.

- Custom Design: The capacity to create a special water pump pulley for special industrial engines.

- World Supply: Exportation to 26 countries and above, guaranteeing you a favorable water pump pulley price in line with the quality requirements of ISO certification.

FAQs

Q1. What is the purpose of a water pump pulley?

Ans: It directs the power from the crankshaft of the engine through a belt and powers the water pump so that the engine can pump coolant.

Q2. What are the symptoms of a damaged water pump pulley?

Ans: Common symptoms are an overheating engine, squealing sounds of the belt, visible wobble of the pulleys, and irregular wear of the belts.

Q3. What type of water pump pulleys material is a good option?

Ans: Steel is standard among ordinary drivers. Billet aluminum is preferable as far as performance is concerned. With heavy duty tractors and generators, cast iron is recommended due to its durability.

Q4. What do I do to change a water pump pulley?

Ans: It entails unscrewing the belt tensioner, taking out the mounting bolts (which may require the use of apulley holder), and then attaching the new one with the appropriate bolt torque settings.

Q5. Are water pump pulleys of the aftermarket reliable?

Ans: Yes, as long as they are obtained from reputable suppliers of water pump pulleys that are CNC-machined and out of high-grade materials.

Conclusion

Water pump pulleys are very important parts of the cooling system of an engine that allow the fluid to flow easily and keep the engine at the best temperature. In automotive and commercial vehicles, tractors, and industrial machinery, the high quality of water pump pulleys allows the serpentine belt to operate efficiently, have a high degree of pulley alignment, and have a durable engine life.

The selection of the material to use, whether it can be aluminum, steel, or CNC-machined corrosion-resistant pulleys are important factors in performance and life cycle. Frequent control check, replacement, and accuracy of installation also avoid the problem of overheating and mechanical breakdowns.

To OEM buyers, aftermarket distributors, and industrial users, the cooperation with highly qualified manufacturers guarantees application-specific solutions that are reliable. Makhija International is a firm specializing in water pump pulleys of high precision, custom production, and high-performance engine cooling products and services to serve a variety of automotive and industrial applications.

Improve engine cooling efficiency with long-lasting, OEM-quality water pump pulleys supplied by Makhija International.