Engine Components Manufacturers: OEM Automotive Engine Parts & Precision Component Suppliers

The automotive and industrial industries of the world seek the services of engine component manufacturers to provide high performance, durable, and precision-engineered components. Whether it is lubrication and cooling to combustion and power transmission, appropriate automotive engine parts manufacturers will guarantee efficiency in the operation of passenger cars, commercial trucks, heavy machinery, and industrial engines.

Key OEM engine components manufacturers and aftermarket suppliers are offering sophisticated solutions through CNC machining, casting, forging, and accurate assembly methods to fulfill the quality standards in the world. To business and procurement executives, strategic partner selection is a process that includes taking a glimpse of the whole manufacturing cycle, including metallurgy and casting, to micron-level CNC finishing and performance testing.

What Do Engine Components Manufacturers Do?

The engine parts industry designs, develops, and manufactures key internal combustion engine components that are needed to support performance, fuel economy, lubrication, cooling, and durability. This is being practiced in such companies as Makhija International through the whole lifecycle management that includes sourcing of cast iron and aluminum of high quality, as well as refining.

A modern engine is a complicated assembly with even a millimeter of misalignment resulting in a catastrophic failure. The industry leading manufacturers today have become one-stop shopping, engineering partners, with fluid dynamics research and validation of the final product.

Key Functions:

- Precision Machining: VMC and CNC technology are used to provide accuracy at the micron level.

- OEM / Aftermarket: Providing parts to build original vehicles, as well as to replace the market.

- Quality Testing: Intensive flow rate, pressure resistance, and thermal stress tests.

- Global Export: The export of precision-machined engine parts to other global markets on continents.

Types of Engine Components Manufactured

1. Components of Lubrication Systems

Any engine is lubricated by blood. Engine oil pump manufacturers focus on producing assemblies that maintain a consistent oil pressure regardless of operating conditions.

- Engine Oil Pump Manufacturers: Manufacturers of gear-driven and rotary pumps that are vital for minimizing friction in heavy-duty diesel engines.

- Components of the engine lubrication System: It contains rotors, gears, and pump housings.

- Sealing Components: Superior-grade gaskets and oil seals to avoid loss of pressure and to ensure that the oil reaches all the galleries located in the far ends of the engine block.

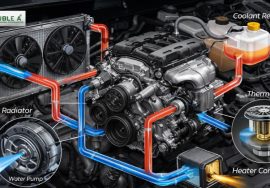

2. Cooling System Components

During the development of engines, the most serious foe is heat as engines are made smaller and more powerful. Manufacturers of parts of engine cooling systems specialize in:

- Water Pump Manufacturers: Design of centrifugal and mechanical pump assemblies, having sophisticated impellers so as to circulate coolant without cavitation.

- Coolant Circulation Parts: It has impellers, shafts, and special housings that are used to keep the “Thermal Window” cool.

- Thermal Management: The components that are used to control the temperatures of the engine during heavy loads and prevent cracking of blocks or failure of gaskets.

3. Power & Timing Components

- Engine Pulley Manufacturers: This company specializes in timing pulleys, idler pulleys, and kits that are required to be perfectly balanced to prevent wobble.

- Crankshaft Pulley Suppliers: Necessary to power the serpentine belt system and make the operation of the accessory smooth.

- Gear Shifter Forks: CNC-machined and made of the most durable material: perfect transmission engagement and over 100 tonne strength.

4. Structural and Peripheral Components

- Engine Manifold Manufacturers: Engine exhaust manifolds and elbows are manufactured to maximize the scavenging and gas flow.

- Cylinder Head Covers: Covers that are made of lightweight aluminum or composite and are used to cover the valve train and make the engine lighter.

Advanced Manufacturing Processes: The Zero-Defect Standard

The competitive advantage of major manufacturers of precision engine components has been in their technological infrastructure. In modern manufacturing, the change towards a smart factory mode is a shift from the manual process.

CNC & VMC Machining

Computer Numerical Control (CNC) and Vertical Machining Centers (VMC) mean that all the bolt holes, gear teeth, and mating surfaces are identical on thousands of units. This is what makes the difference between a normal replacement component and an OEM-level component.

Die Casting & Forging

- Cast Iron Components: Cast iron components are the choice of heavy-duty exhaust manifolds and oil pump housings because they are more resistant to heat and vibration.

- Aluminum Die-Casting: This is preferable to the lightweight engine parts manufacturers as a method of enhancing fuel efficiency because of the lower mass of the entire vehicle.

Testing & Metrology

The leading manufacturers do not examine the quality only at the end, but they check it at all levels. There are facilities such as the Makhija International, which make use of:

- CMM (Coordinate Measuring Machines) & VMM: To verify the dimensions on a micron scale.

- 3D Scanning: 3D scanning is applied in inspection as well as reverse engineering of old or specialized engine components.

- Endurance Testing: Simulation equipment in-house that is able to test flow rate, leak resistance, and pressure rating.

OEM vs. Aftermarket: Strategic Sourcing

In sourcing parts, businesses have to face the decision between OEM (Original Equipment Manufacturer) and Aftermarket solutions.

| Segment | Market Role | Key Benefit |

| OEM Engine Parts Manufacturers | Supply directly to the vehicle assembly line. | Guaranteed fitment and “Zero-Risk” performance. |

| Aftermarket Suppliers | Provide replacement parts for repair and maintenance. | Cost-effective solutions for fleet upkeep. |

| Engine Components Exporters | Focus on global supply chains and bulk distribution. | Expertise in international shipping and private labeling. |

Successful companies are capable of bridging these worlds. They apply the highest level of engineering to their global aftermarket exports in more than 26 countries by supplying over 12 large OEM companies, including correcting their supply chains of major brands.

Industry Applications: From Fields to Highways

The scope of the influence of heavy machinery engine parts is very broad in the global economy:

- Agriculture: Tractor engine components and harvester components that are designed for high dust and high heat conditions and 12-hour work shifts.

- Automotive: Commercial trucks, LCVs, and passenger cars that need high RPMs.

- Construction and Mining: Engineer hydraulic pumps and earthmover engine pulleys designed to be as powerful and as tough as possible, even in extreme scenarios.

- Power Generation: Components of industrial generators that are designed to be used in hospitals and data centers with constant on reliability.

Advantage India: The Hub for Global Sourcing

India has become a force in the automotive engine parts OEM suppliers. Indian manufacturers are increasingly gaining popularity among global buyers because of several reasons:

- Cost-Efficiency: Huge cost benefits in comparison to Western markets without losing technical quality.

- Expert Workforce: A vast number of engineers in fluid mechanics, metallurgy, and sophisticated machining.

- Government Support: This gives incentives to the government so that companies are able to produce high-tech products, and companies are able to invest in CNC world-best, VMC, and R&D facilities.

Choosing the Right Engine Components Manufacturer

To choose the appropriate partner, it is necessary to have a checklist of non-negotiable standards:

- Manufacturing Infrastructure: It is important to have in-house casting, CNC, and testing facilities.

- Quality Standards: Seek the IATF 16949 and ISO certification that guarantees the international standards of quality assurance in terms of safety and reliability.

- Customization Capability: This refers to the ability to deal with custom engine component production on the basis of certain CAD drawings or reverse engineering.

- Track Record: A manufacturer that has a long history has the stability that is necessary in the complex engine projects.

Conclusion

Manufacturing of professional engine components is an important contributor to the provision of reliable, fuel-saving, and high-performance engines. With engine oil pumps manufacturers to dedicated manifold manufacturers, the industry is now advancing through precision engineering, intelligent automation, and tactical OEM collaborations. The best method of ensuring the durability, operation efficiency and long term values of your vehicles or machineries are by selecting the appropriate automotive engine parts suppliers.

Makhija International Private Limited is a reputable market leader in this field, with both high-end manufacturing presence and international exporting coverage. Their provision of accurate manufacturing cooling, lubrication, and peripheral engine solutions ensures that industries such as agriculture and automotive keep on going with no downtime.

Today, visit Makhija International to find a complete variety of precision-engineered engine parts, oil pump assemblies, and high-performing cooling solutions that are made to meet the most challenging industries in the world.

FAQs

Q1. What are the components of engine manufacturers?

Ans: They manufacture some of the critical internal and peripheral engine components, including oil and water pumps, manifolds, shifter forks, and pulleys of various machines.

Q2. Which industries are dependent on them?

Ans: Automobiles, agricultural (tractors), marine, power generation, and construction equipment are considered the key sectors.

Q3. What causes the distinction between OEM and aftermarket engine parts?

Ans: OEM components are the same as those installed in the factory, whereas aftermarket components are manufactured as an option to substitute for repair and maintenance markets and performance upgrades.

Q4. What materials are the manufacturing materials?

Ans: Typical ones are high-grade cast iron, aluminum alloys, stainless steel, and machined forged steel.

Q5. What is the importance of such certification as IATF 16949?

Ans: They also keep the manufacturer to high global standards of quality in terms of safety, reliability, and prevention of defects in the automotive supply chain, in particular.