Automotive and Non-Automotive Water pumps manufacturers: Global manufacturing and Supply Guide

In a high-pressure field such as mechanical engineering, thermal control is the difference between optimum performance and explosion. The quality of the cooling system components is all that is needed to guarantee the effectiveness of a cooling system in a long-haul commercial truck or a mission-critical industrial generator. This guide will examine the variety of automotive and non-automotive water pumps manufacturers and their contribution in terms of technical advancement and accuracy of engineering development that leads to industry reliability in modern times.

Evolution of Water Pump Manufacturing in Mobility & Industry

The water pump has made a transition from being a mere mechanical displacement to advanced thermal management.

- Early Mechanical Cooling Pumps: The manufacturers of water pumps serving the engines traditionally concentrated on centrifugal designs, which were belt driven. These were dependable, but had speed-dependent over-cooling and under-cooling depending on the engine RPM as opposed to actual thermal load.

- Switch to High-Efficiency Systems: The current-day coolant pump producers have resort to the use of computational fluid dynamics (CFD) to achieve the optimal geometry of the impellers to minimize parasitic power loss and maximize the flow rates.

- Modern Thermal Management: The manufacturers of thermal management pumps are now introducing electronics. It is no longer needed to pump liquid but rather intelligent heat control whereby the pumps would talk to the ECU of the vehicle and keep the vehicle at the preciseness of the temperature range.

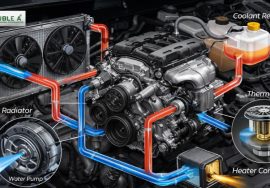

Why Water Pumps Are Critical for Machine Reliability

A water pump is not just a utility but it is a protection. There are four areas that are addressed by performance engine water pumps:

- Heat Control: The modern engines operate at higher temperatures to minimize emissions, and the work of the coolant circulation pump manufacturers is critical to the cooling down of the engine.

- Constant Circulation: The machines used in industries, primarily mining and power plants, need 24/7 circulation to avoid the formation of hot spots in specific areas that have the ability to bend cylinder heads.

- Fuel Efficiency: The high-quality pump can lead to higher quality by adjusting the flow rate, which directly leads to improved mileage and decreasing the amount of CO 2 emitted by the engine.

- Downtime Mitigation: A pump failure is not a fix, as it is in the industrial world, it is a stoppage in production. To avoid these million-dollar risks, manufacturers of high-tier heavy-duty water pumps put the emphasis on longevity.

Engineering Design & Pump Architecture

The secret sauce of the highest-performing automotive water pump producers is in the design of the unit:

- Impeller Dynamics: The major water pump manufacturers have developed impellers of polymer or stainless steel that reduce cavitation, the creation of vapor bubbles, which may erode metal surfaces with time.

- Flow Rate Optimization: The Advanced high flow water pump manufacturers make sure that the pump will be able to transport huge amounts of coolant even when it is at a low idle speed.

- Pressure Balancing: Accurate seals and bearings are used to guarantee leak-proof operation of the pump in the high-pressure conditions of the modern-day pressurized cooling systems.

Product Portfolio: From Mechanical to Electric

The market is now divided into a number of specialized segments:

| Pump Type | Typical Application | Key Benefit |

| Mechanical Water Pumps | Heavy Trucks, Tractors, Older ICE Vehicles | Extreme durability and simplicity. |

| Electric Coolant Pumps | EVs, Hybrids, Auxiliary Cooling | Independent control from engine speed. |

| Centrifugal Water Pumps | HVAC, Industrial Generators | High-volume fluid movement. |

| Gear Driven Pumps | Heavy-Duty Diesel Engines | Zero belt-slip; direct power transfer. |

Application-Based Manufacturing Segments

Cooling in the Automotive Industry

From passenger vehicles to commercial vehicles, it is all about lightweight durability. Some of the water pumps specially made by the automotive & non automotive water pumps manufacturers of the diesel engines are designed to survive the high-torque, high-heat environment of the long-haul logistics and agricultural machinery, and the water pump manufacturers design to survive the dust-and-dirt environment of the tractors.

The Cooling of Industrial Applications

The manufacturers of the generator cooling water pump serve the power sector, where the pumps should work thousands of hours continuously without being serviced. On the same note, marine water pumps manufacturers adopt special alloys to avoid the corrosive saltwater and humidity.

Raw Materials & Manufacturing Workflow

Installation of water pump components CNC machined begins at the foundry stage.

- Cast Iron Housings: These are ideal to use when there is heavy vibration dampening and thermal shock resistance.

- Aluminum Die-Cast Bodies: Bodies that automotive water pump exporters use in order to lower the weight of vehicles.

- Precision Workflow: This is done by casting, high precision CNC machining, dynamic impeller balancing, and 100% leak and pressure testing of the unit prior to boxing.

Competitive Advantages of Indian Manufacturers

India has turned out to be the world’s centre for the supply of bulk water pumps. Indian manufacturers of water pumps, such as Makhija international provide:

- OEM-Grade Engineering: As an OEM manufacturer of water pumps of world renown brands.

- Cost-Efficiency: The infrastructure is developed at high levels that make it possible to produce high-quality products at competitive prices.

- Scalability: It is capable of managing small-lot, custom orders of niche industrial engines or huge orders of automotive lines.

Conclusion

When choosing reliable companies in production of automotive & non automotive water pumps manufacturers, it is crucial that the company maintains efficient cooling of the engine, minimizes thermal stress, and that the company will continue to operate efficiently in the long run across the fleet of vehicles and industrial equipment.

In businesses where needs are highly engineered, Makhija International Private Limited provides high performance automotive & non automotive water pumps manufacturers. They have a 45 year heritage and operate in more than 26 countries with ISO certified processes coupled with high-quality CNC-machined water pump components to establish the standard of the industry. Visit Makhija International in order to see what their entire variety of water pump products, OEM manufacturing services, and customized cooling systems have to offer.

FAQs

Q1: What suppliers are automotive water pumps and non-automotive water pumps?

Ans: They provide passenger cars, commercial trucks, agricultural tractors, generators, marine engines, and coolant pumps.

Q2: What is the role of an engine water pump?

Ans: It disperses coolant between the radiator and the engine block to ensure the optimum operating temperature and avoid overheating.

Q3: Do the electric water pumps outperform the mechanical pumps?

Ans: The electric pumps are more efficient as they can be used without being dependent on the engine speed; however, for the high-durability, heavy-duty applications, mechanical pumps are the standard.

Q4: Are there industrial demands for water pumps?

Ans: Power generation (generators), mining, marine propulsion, agriculture, and large-scale construction are some of the key industries.

Q5: What are the materials are used to make durable water pumps?

Ans: The housings are generally of high-grade cast iron or aluminum, and the shafts are made of stainless steel, and the seals are of high-grade silicon carbide.

Q6: What is the reason to source out to the manufacturers of Indian water pumps?

Ans: The water pump manufacturers in India provide a combination of quality engineering aspect, IATF/ISO quality, and low-priced industrial scale production.